In-House Repairs

Should it not be possible to carry out a repair on-site in a particular case, we also offer an ideal solution for this kind of situation: our in-house repair service.

At our location in Rosengarten-Uttenhofen, we have the best facilities which allow us to carry out repairs on your fans or compressors in a long-lasting, efficient and fast manner. In order to reduce your logistics workload, we can also organize the collection and transportation of your machine upon request.

Your machines and components are always in the best hands with our expert repair specialists.

Our services:

- Fault diagnosis, damage surveys and functional testing

- Penetrant testing (PT) and magnetic particle testing (MP) on delivered impellers and housing

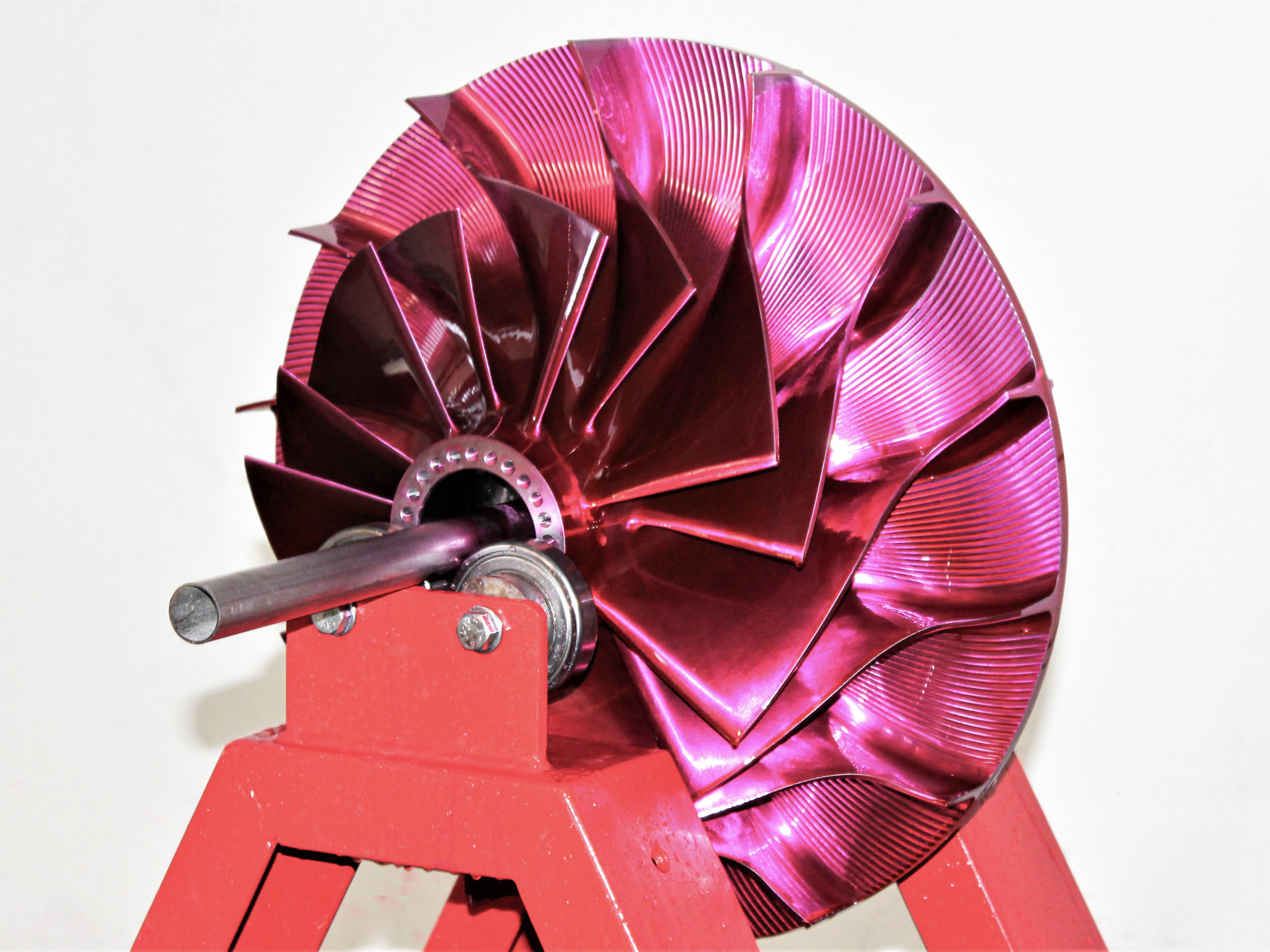

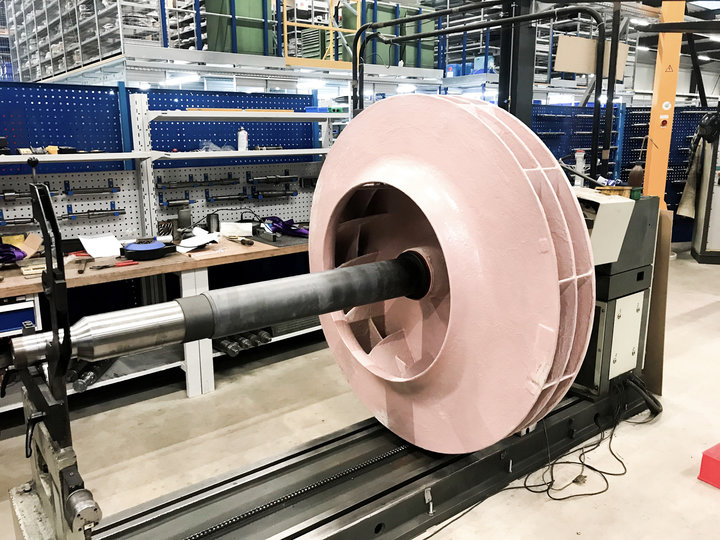

- Refurbishment of components such as impellers, bearings, shafts and other components

- Balancing impellers

- Repair and fault correction: Assembly of OEM-quality spare parts

- Test run with all the tests which are relevant to quality

- General overhaul

Field Balancing

Unbalance is a physical phenomenon that is always associated with rotating components. With fans and compressors in particular, dirt deposits, minor damage and wear during operation leads to increasing unbalance. Sooner or later, this leads to damage to machines, foundations and buildings. This phenomenon needs to be counteracted.

Our specialists can also offer you a suitable alternative to field balancing for this. Impellers and rotors which have been delivered are refurbished and balanced by our specialists. We carry out the balancing process in accordance with ISO 1940 during rotation - dynamically at two levels, as well as statically at one level.

Get in touch with us and we’ll solve your balancing problem!

Non-Destructive Testing

Non-destructive testing is used to examine work pieces and components without changing and/or damaging their function or integrity. One of the most commonly used procedures in connection with this is dye penetrant testing (FE testing) or magnetic particle testing (MP testing).

Using FE or MP testing, the Serafima expert team is able to identify faults on surfaces made of metallic and other non-porous materials. Faults in components such as impellers or housing can therefore be identified at an early stage and remedied, thus preventing more serious damage.